Capability

CNC Milling

| Machine Name | Machine Type | X axis (mm) | Y axis (mm) | Z axis (mm) | Max Weight (Kg) |

|---|---|---|---|---|---|

| Ajax | Mill | 2550 | 940 | 1000 | 4500 |

| Bridgeport VMC1000/30 | Mill | 1017 | 452 | 481 | 900 |

| Haas VF10 | Mill | 3048 | 813 | 762 | 1814 |

| Haas VF3 | Mill | 1016 | 508 | 635 | 1588 |

| Haas VF5 | Mill | 1270 | 660 | 635 | 1588 |

| Haas VF6 | Mill | 1625 | 813 | 762 | 1814 |

| Haas VF7 | Mill | 2134 | 813 | 762 | 1814 |

| Haas VF8 | Mill | 1626 | 1016 | 762 | 1814 |

CNC Turning

| Machine Name | Machine Type | Chuck Diameter (mm) | Chuck Thru Hole (mm) | Ø Under Saddle (mm) | Length Between Centres (mm) |

|---|---|---|---|---|---|

| Colchester 4000 | Lathe | 300 | 102 | 360 | 1720 |

| Colchester K4 | Lathe | 400 | 102 | 370 | 1900 |

| Combi 4000 | Lathe | 300 | 102 | 370 | 1750 |

| Combi 6000 | Lathe | 530 | 170 | 500 | 2650 |

| Combi 6000 LB | Lathe | 530 | 170 | 500 | 3800 |

| DSG | Lathe | 920 | 279 | 781 | 4191 |

| Puma 400 L | Lathe | 380 | 115 | 500 | 1702 |

| Puma 400 LM | Lathe | 450 | 115 | 600 | 2000 |

| Puma 700 | Lathe | 800 | 160 | 790 | 3000 |

Mill / Turn

CNC VERTICAL MILL/TURN

| Machine Name | Machine Type | X axis (mm) | Y axis (mm) | Z axis (mm) | Max Weight (Kg) |

|---|---|---|---|---|---|

| Mazak 1850 | Vertical Mill/Turn | 2130 | 1850 | 1840 | 3500 |

| Mazak E1060 | Vertical Mill/Turn | 1625 | 1060 | 1345 | 1800 |

CNC HORIZONTAL MILL/TURN

| Machine Name | Machine Type | Chuck Diameter (mm) | Chuck Thru Hole (mm) | Ø Under Saddle (mm) | Length Between Centres (mm) |

|---|---|---|---|---|---|

| Mazak E500 | Horizontal Mill/Turn | 630 | 160 | 700 | 3200 |

| Mazak E650 | Horizontal Mill/Turn | 610 | 155 | 460 | 6100 |

| Puma MX | Horizontal Mill/Turn | 305 | 75 | 500 | 1100 |

| Puma MX | Horizontal Mill/Turn | 380 | 75 | 500 | 1000 |

| Puma SY | Horizontal Mill/Turn | 210 | 61 | 650 |

Wire & Spark Eroding

| Machine Name | Machine Type | X axis (mm) | Y axis (mm) | Z axis (mm) | Max Weight (Kg) |

|---|---|---|---|---|---|

| AG600 | Wire | 600 | 400 | 350 | 1000 |

| Agie | Spark | 602 | 300 | 400 | 800 |

| K1C | Spark | 200 | 300 | 210 | 100 |

| Mecrode | Spark | 640 | 300 | 370 | 800 |

Holistic Precision

The basic nature of our business is to receive drawings and deliver parts, but we understand that our clients need much more than just a part delivered to the drawing. As a customer oriented organisation, Hyspec Engineering delivers services which are beyond simply precision, or accuracy. We are an organisation that has “precision” as a fundamental ideology driving all aspects of our business. We pursue a holistic precision management ideology to ensure that our clients are able to experience this attention to detail in every aspect of our business, whether it is reliability, responsiveness, communication, knowledge, continuous improvement, risk management or co-operation. We want to deliver for our clients. Precision for us is not only about quality and scope of work but it’s also about our ability to partner with our clients in helping them achieve their vision.

Kits and Assemblies

Hyspec has been supplying Mechanical, Hydraulic and Pneumatic kits and assemblies to different sectors across the globe for decades. These assemblies consist of machined parts and purchased parts, all tested and certified to customer requirements at minimum prior to shipment.

Using our standardised documentation practices across our business operations, all necessary paperwork is provided, along with a full certificate of conformity at the completion of each job.

Supplying assemblies and kits can save our customers time and space, and reduce their inventory cost; and since all of the parts can be traced through a single supplier, we help to save customers time and money during their RFQ process.

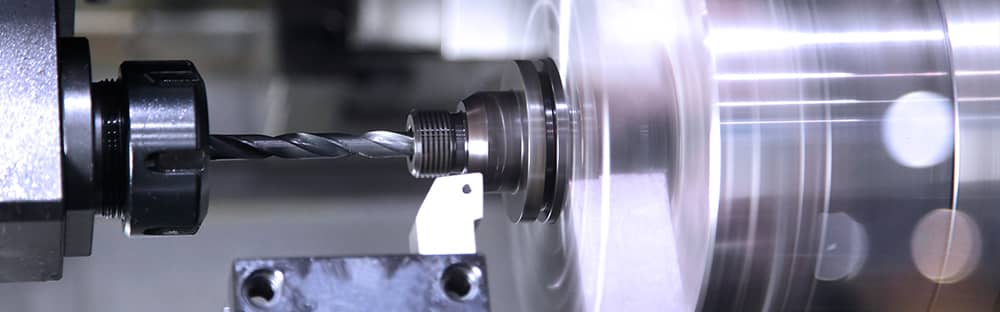

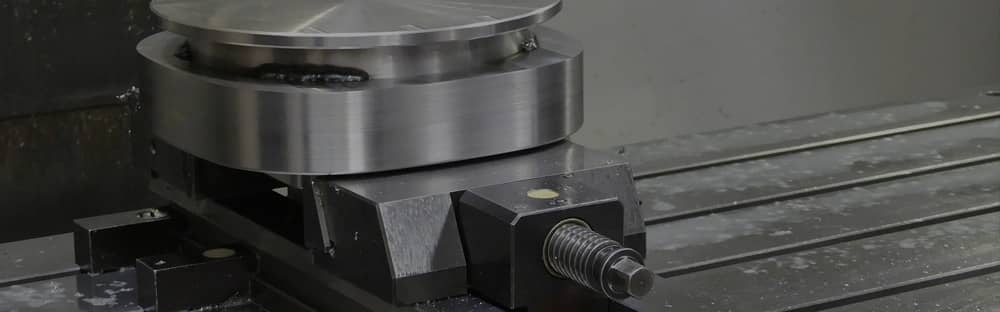

Precision Machining Parts

Hyspec Engineering has been satisfying the precision machining and engineering needs of clients for nearly four decades. Our highly skilled workforce and sophisticated machine tools make us the only company you need for all your precision machining requirements. Our workshop hosts some of the finest machine tools which allow us to deliver parts ranging from 10mm to 2.5 metres in diameter, and 3 metres in length.

While we are renowned for our ability to deliver complex parts, we are equally adept at the regular, low complexity batch production. From our state of the art Scottish headquarters covering over 33,000 square feet, Hyspec is well placed to serve engineering clients across the globe.

Hyspec stands for versatility, sophistication and above all precision. We understand how critical our services are to your business and are always sensitive to your requirements.